King’s Pride Refit Blog

Rudder, Part 1

One big part of this refit is the steering system. Steering is a major concern when purchasing an older vessel because loss of steerage on a boat is never a good thing, it can cause loss of life, the vessel, and potentially put other people in harms way. King’s Pride came with Edson steering and it performed very well during our 11-mile journey to Anacortes, although we didn’t get to sail the vessel. Jennifer reported the steering worked very well and they never had any problems with it. The rudder managed to drip and ooze for the first 36 hours after haul-out, indicating we needed to have a look inside it!

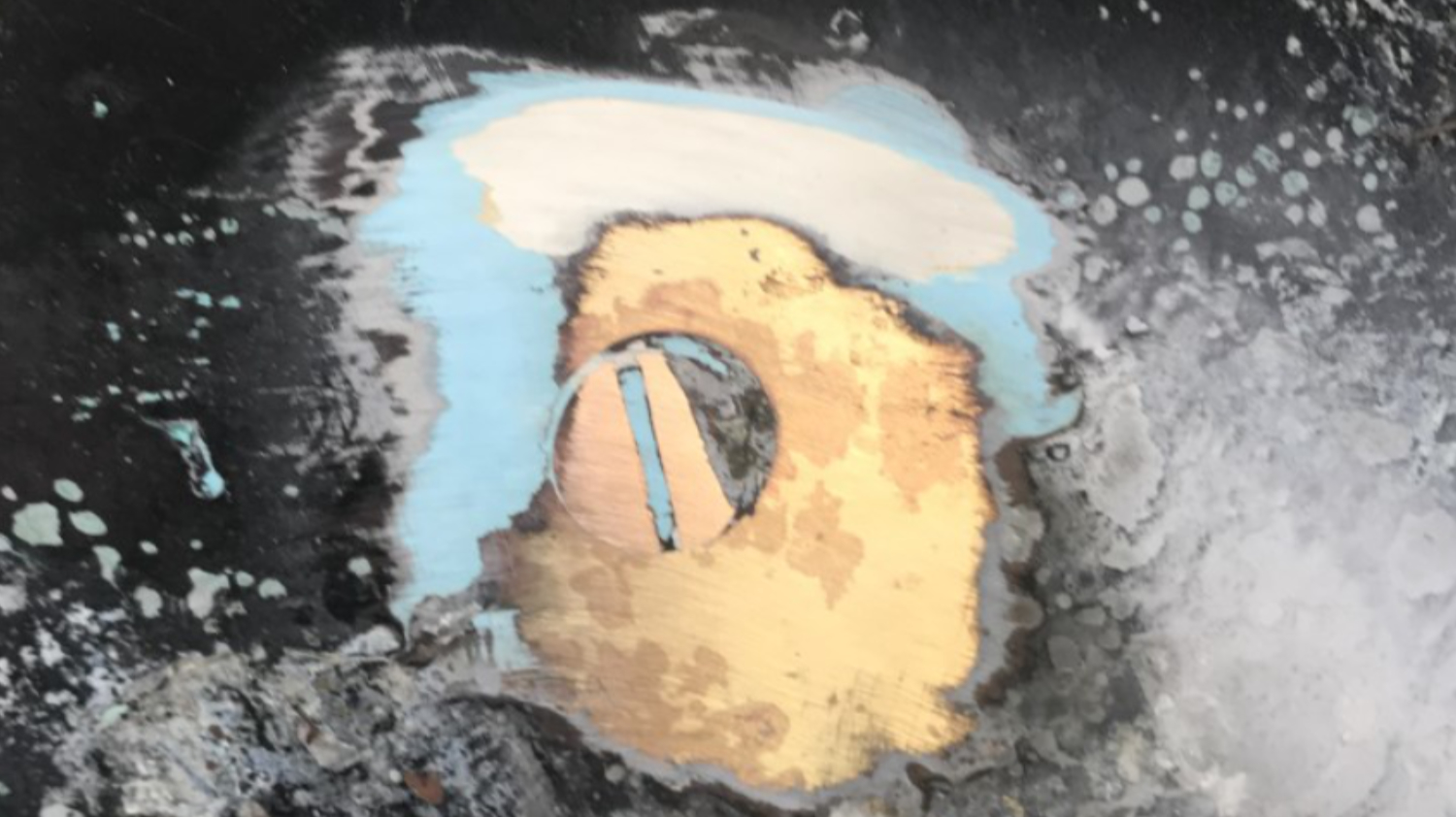

The first step was to remove the gudgeon, no small task! We used an impact driver, backed up with our forklift on the other side. We broke two of them off and had to drill them out. Then we had to find the seam and warm the bronze to get a little expansion. With some wedges, the heat, and encouragement they got it off. Normally we have 2 people working a 4-hour shift, and this task was it for day 1.

The next day was up inside the vessel removing the cables and the sheaves. Sounds easy, but remember it’s a sailboat, and almost 40 years old. There went another 4-hour shift, but they accomplished the goal – Art did jump in and use some of his “Language Encourage” to let that corroded ____ ____ know who was in charge. This was definitely needed as the top looked great, but the bottom was corroded, comprised, and generally unsafe for use from all the years of saltwater splashing on it.

On the third day, we were ready to remove the rudder. Only 1 problem, the tape measure doesn’t lie…. We were 4” short from being able to remove the rudder. What to do? One option was to bring in the travel lift – a little expensive and time consuming. Option 2: remove asphalt and dig a hole – not ideal & my boss might not like us destroying school property. Option 3: cut the rudder post up high in the vessel and repair later. We opted for this option for a couple of reason. The rudder has 3 support locations and only the lower two are needed for normal operation – the upper ‘bearing’ is for when the emergency tiller is working. This was a poorly designed system and we wanted to upgrade it. So some fabrication was going to be needed anyway. About 2 minutes with a 4” grinder and cut off wheel did the trick! Rudder is now in the shop and ready for part 2.